Features and benefits

AVK diaphragm operated control valves are the safe choice. They are designed according to EN 1074-5 and to provide network stability, accurate regulation, easy maintenance and long durability.

Unique design features

AVK control valves are the safe choice offering accurate regulation, easy maintenance and long durability:

All non-coated metal parts of stainless steel AISI 316 as standard

Fusion bonded GSK approved epoxy coating (300 micron)

AVK's own drinking water approved rubber compounds

Modular pilot system enables easy fitting to other applications without replacing the valve

Independent adjustment of opening/closing speed for full control

Parabolic plug design provides precise regulation and stability at low flow

Large diaphragm secures fast reaction to minor changes in pressure

Lifted seat prevents damage inside the valve body due to cavitation

AVK design and manufacture with 100% pressure test and 10-year warranty

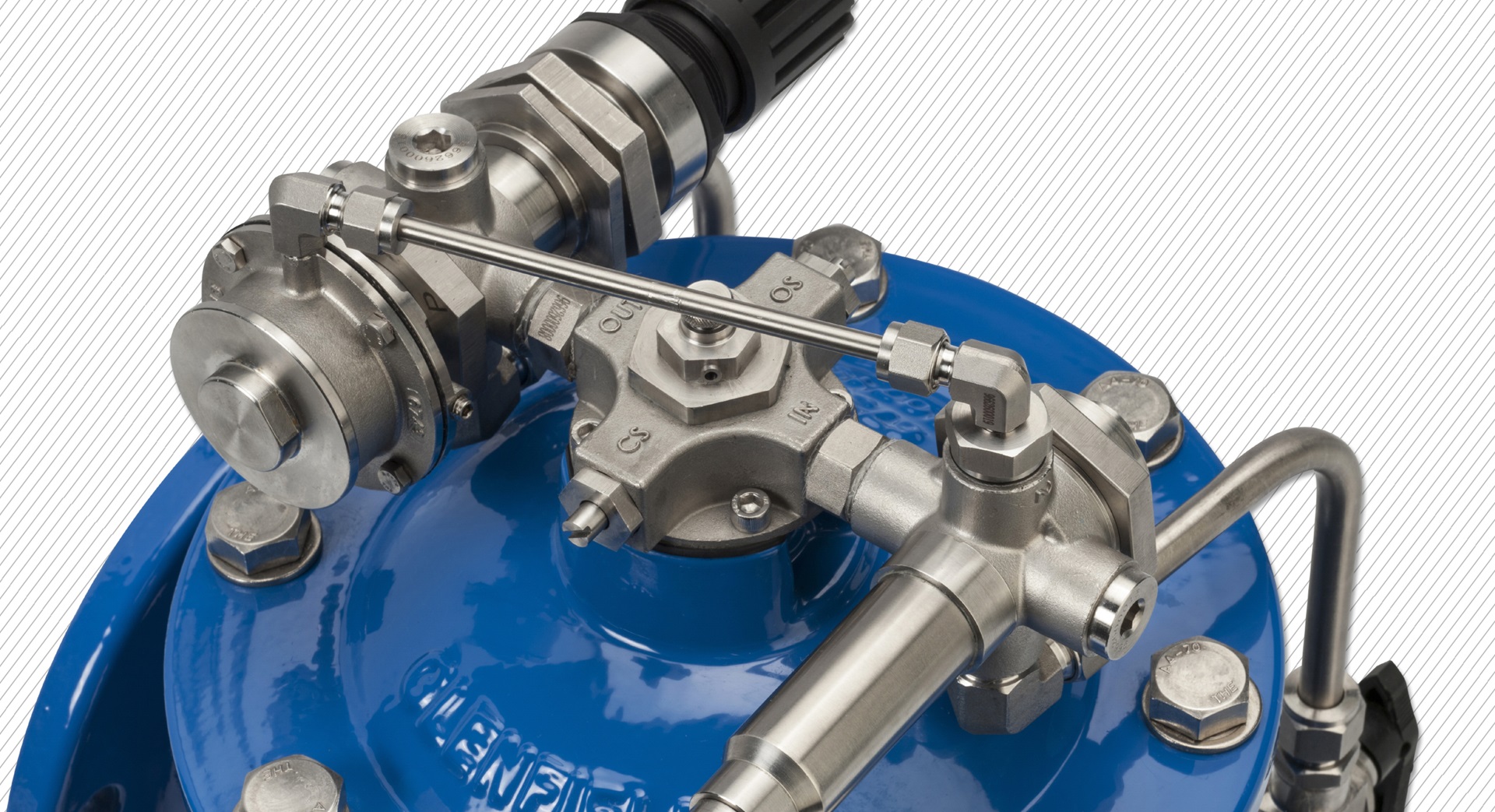

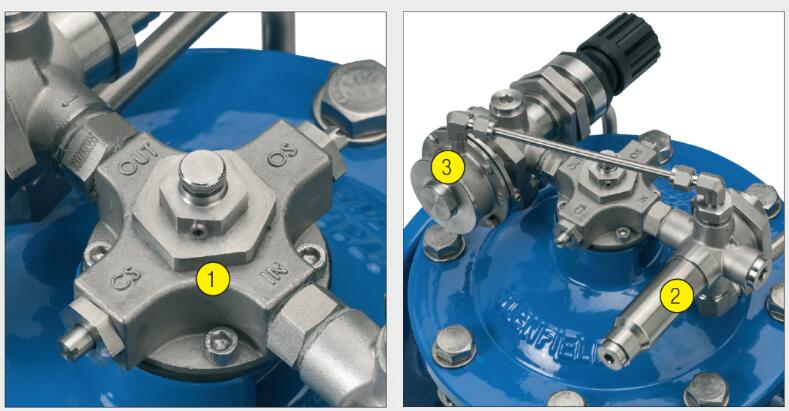

Patented modular pilot system

The modular design with interchangeable parts offers great flexibility as the pilot system is easily altered to fit other or multiple applications without replacing the valve. The pilot system consists of three main components:

The distribution block (1) connects the pilot system to the main valve. As a unique feature, it offers independent opening and closing speed, easily adjusted using standard tooling, and giving full control e.g. in situations, where water hammer may occur.

The filter (2) features high capacity and easy maintenance. When using the optional flush valve it also offers easy access to cleaning, while the valve is in operation.

The hydraulic control block (3) can be set up for different applications. It features easy hand adjustment of the balanced pilot valve which is capable of very precise settings.

The external pipework takes up less space and is less vulnerable to damage during installation compared to many other control valves. It is designed using components with standard threads offering easy sourcing of replacements as well as easy fitting using standard tools. All metal parts are of stainless steel AISI 316.

Valves of high quality materials

The body and bonnet are made of ductile iron with fusion bonded GSK approved epoxy coating. The diaphragm is manufactured by AVK GUMMI and made of drinking water approved EPDM rubber with polyamide reinforcement. All non-coated internals are of stainless steel AISI 316 and all materials are WRAS approved.

AVK control valves are available in DN50-300, with reduced and with full bore. Control valves with reduced bore are appropriate for most applications, as the smaller bore often offers more accurate regulation. Control valves with full bore are recommended, if high Kv values are needed, e.g. in front of hydrants.

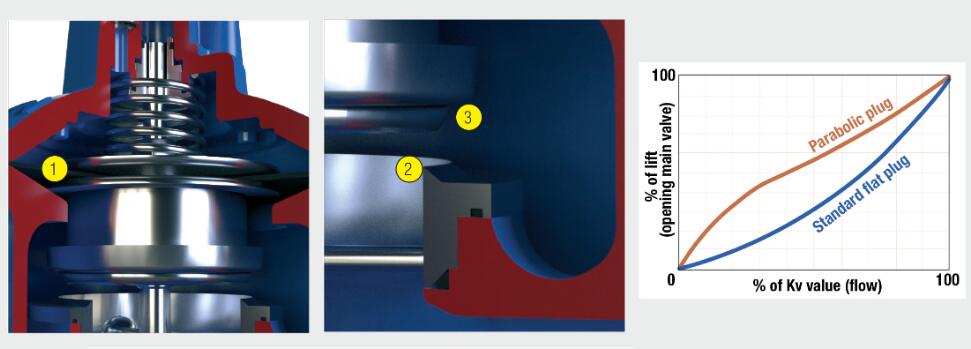

Large diaphragm design (1) secures fast reaction to changes in pressure. Its asymmetric axial position gives less stress near closed position.

Lifted seat design (2) prevents damage inside the valve body caused by cavitation.

Parabolic plug design (3) provides precise regulation and stability at low flow. Furthermore, it reduces noise and vibration. See characteristics, illustrating the performance compared to a standard flat plug design.