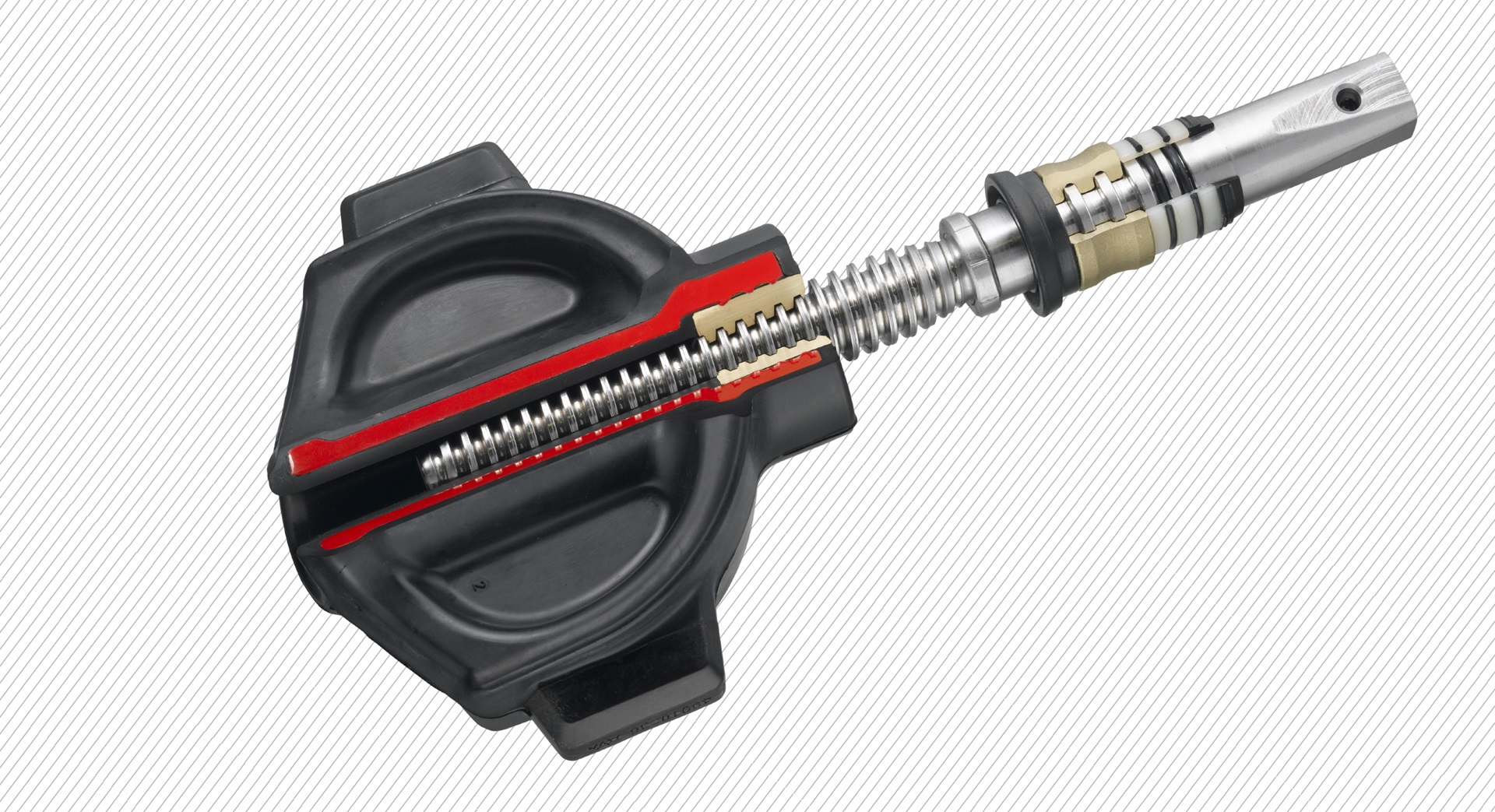

Unique wedge design

The wedge is the heart of a gate valve and the design and rubber quality are crucial for the valve function and durability. AVK wedges feature a unique fixed wedge nut design and are fully vulcanised with AVK¡¯s own rubber compound offering outstanding characteristics.

Fixed wedge nut and wedge shoes ensure smooth operation of the gate valve

AVK¡¯s wedge nut design with a fixed, integral wedge nut outperforms the traditional loose wedge nut design as it prevents vibration and thus also wear of the rubber surface and corrosion. It is made of low lead brass approved for drinking water according to the stringent EU standards.

The fixed wedge nut and the guide rails fitted with vulcanised wedge shoes secure a smooth operation of the gate valve and low operating torques. The wedge shoes protect the rubber against the wear which otherwise would arise from friction during operation. The wedge shoe is made of drinking water approved polyamide and is fully vulcanised to the wedge core for maximum corrosion protection.

State-of-the-art rubber technology

AVK GUMMI A/S develops and manufactures rubber compounds using highly advanced technologies. The wedge core is immersed in two different baths to provide ultimate bonding between core and rubber. Even if a sharp object penetrates the rubber during closing of the gate valve, the bonding is so strong that there is no risk of creeping corrosion.

Rubber with excellent ability to regain original shape

AVK¡¯s rubber compounds have an unrivalled compression set, meaning its ability to regain its original shape after having been compressed. Impurities will be absorbed in the large layer of rubber in the sealing area when the gate valve is in closed position ensuring a 100% tight sealing. They are flushed away when the valve is reopened and the rubber will regain its shape.

AVK gate valves do not contaminate the drinking water

The EPDM rubber recipes are composed with focus on minimising the formation of biofilm. The rubber will therefore not provide breeding ground for bacteria. The drinking water approved EPDM compounds are resistant to ozone and water treatment chemicals, and will remain flexible preventing cracks and damages. The compounds are of course taste, smell and colour neutral.

Find more details on AVK's unique rubber.